|

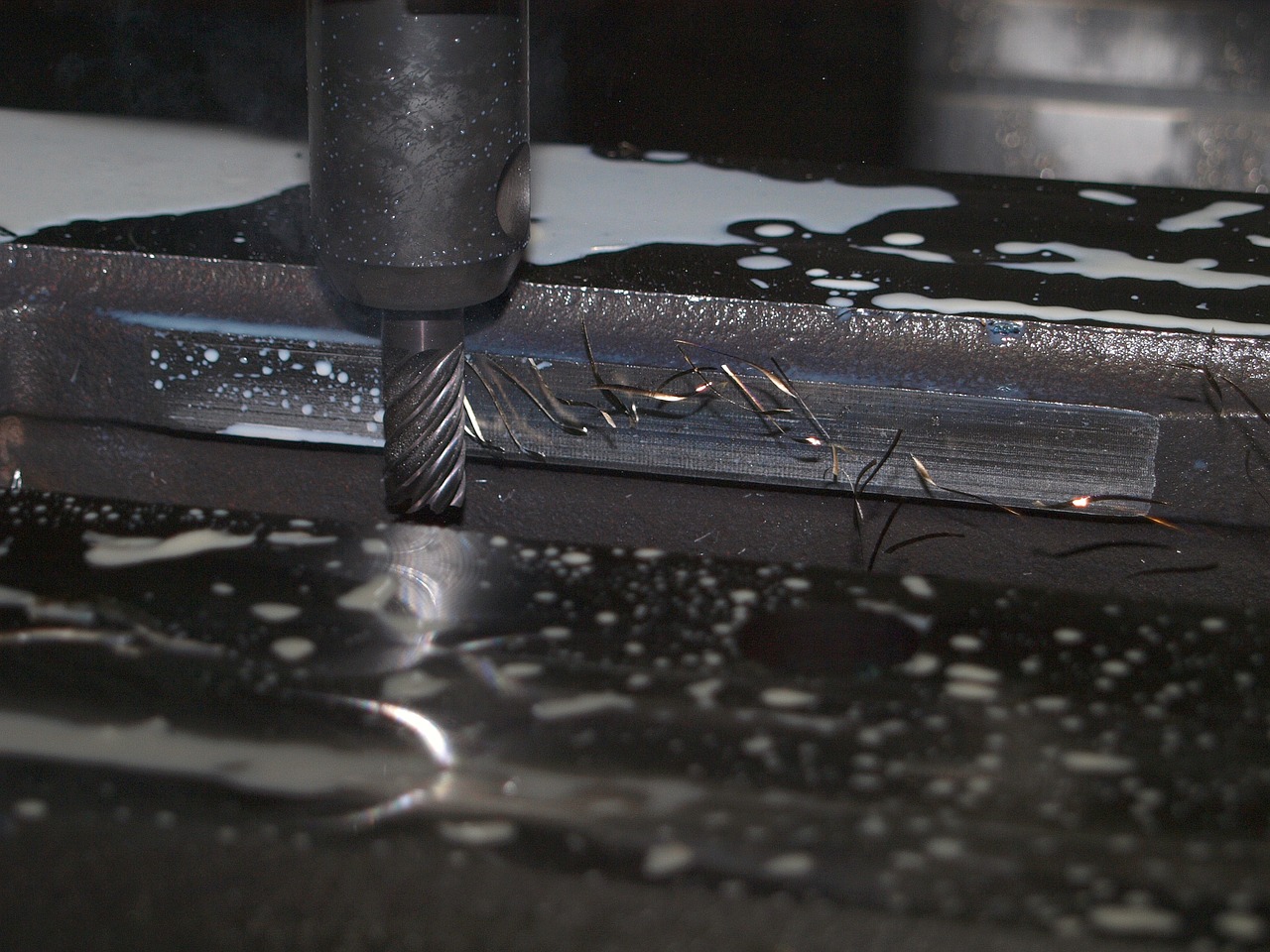

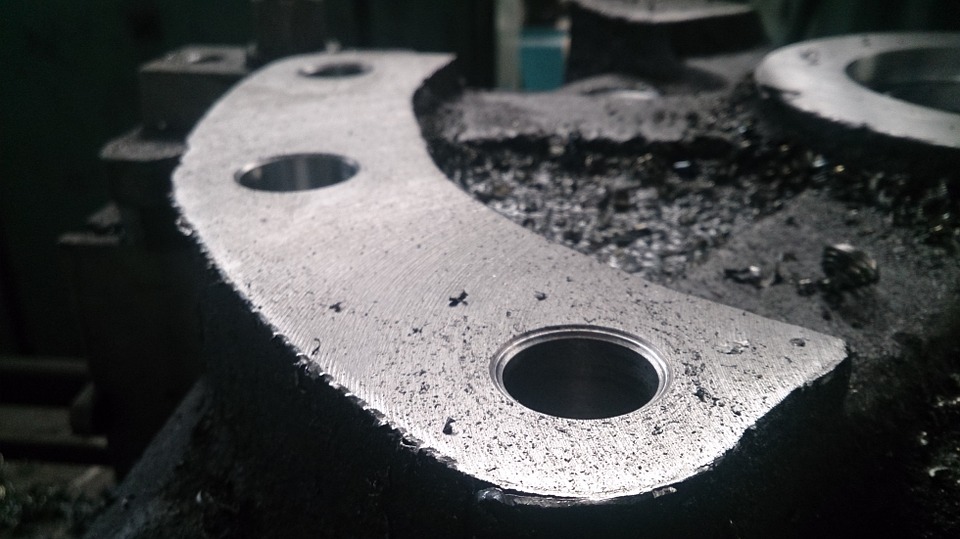

We specialize in mass production of elements and components using the newest CNC technology and machinery. Our machine park includes numerical control: vertical, horizontal and universal machines to process elements. The efficiency and versatility of our machines, that allow the milling of elements from 4 and 5 different angles with fixing it only once, allows us to produce practically every detail with great accuracy and precision. Our robust centre of conventional machines supplements our CNC lathes and allows us to produce individual details or prototypes. Materials we use include:

Our capabilities include: Universal CNC 5 axis machining Maximum worktable dimensions: 1280x800 mm Maximum movement: X 1000 mm

Y 660 mm

Z 800 mm

B 360 x 0,001°

Vertical CNC 3 axis machining Maximum worktable dimensions : 2000x500 mm

Maximum movement :

X 1600 mm

Y 420 mm

Z 480 mm

Conventional milling Maximum worktable dimensions : 1800x320 mm Conventional Boring Maximum worktable dimensions: 1000x600 mm

Scope of bored diameters: FI 5-300 mm

Conventional drilling Maximum worktable dimensions: 800x500 mm

Maximum drilling diameter: FI 50 mm

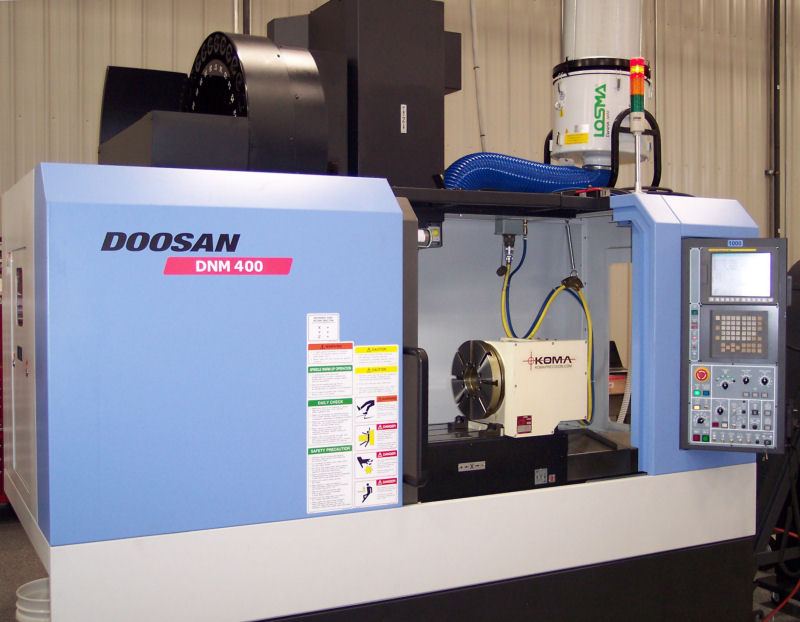

Our machines: Vertical machining:

Universal machining:

Horizontal machining (two pallet system):

|

|